Advantages:

- Beam sensitive materials are stabilized under high beam currents

- Low-temperature phases can be studied

- Enhanced imaging and spectroscopy, especially for cathodoluminescence (CL)

| Model # | Base temp. | Cool down time | Max. operating temp. | Tilt | Rotate | Additional electrical feedthrough option | |

|---|---|---|---|---|---|---|---|

| C1001 | -185 °C | 10 min | 50 °C | 45° | ±5° | √ | |

| C1002 | -185 °C | 10 min | 200 °C | 45° | ±5° | √ | |

| C1003 | -185 °C | 10 min | 400 °C | 45° | ±5° | √ | |

| CF302M | 8 K | 55 min | 140 K | ±5° | √ | ||

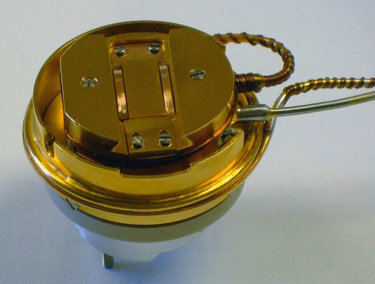

Liquid nitrogen cooling stages C1001, C1002, C1003

- Simple installation/removal allows use of standard SEM stage

- Stages cooled to less than -185 °C by nitrogen gas

- Efficient thermal design ensures rapid cool down and stable temperatures

- Accurate control through integral heater and temperature sensor

- External liquid nitrogen heat exchanger removes vibration due to boiling of LN2

- Higher upper-temperature options for more flexibility in experiments

Liquid helium cooling stage CF302M

- Specially designed low drift and vibration, while minimizing liquid helium consumption

- CF302M is a helium-cooled stage module that attaches onto the existing stage

- Complete system includes flexible transfer tube storage vessel, top fitting with bladder and valve, gas flow controller, gas flow pump, and digital temperature controller

Dual fuel option

- Allows liquid helium cold stages to be operated with either helium or nitrogen

- Functions by forcing cold nitrogen gas through the circuit similar to the successful C1002 product

Control of amorphous solid water target morphology induced by deposition on a charged surface

High Power Laser Science and Engineering

2021