Recent Publications

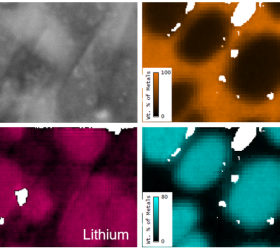

Phenomenological understanding of the contribution of bulk and grain boundary precipitates on strengthening in prolonged-aged Al-Zn-Mg-Cu aluminium alloys

Materials Today Advances

2025

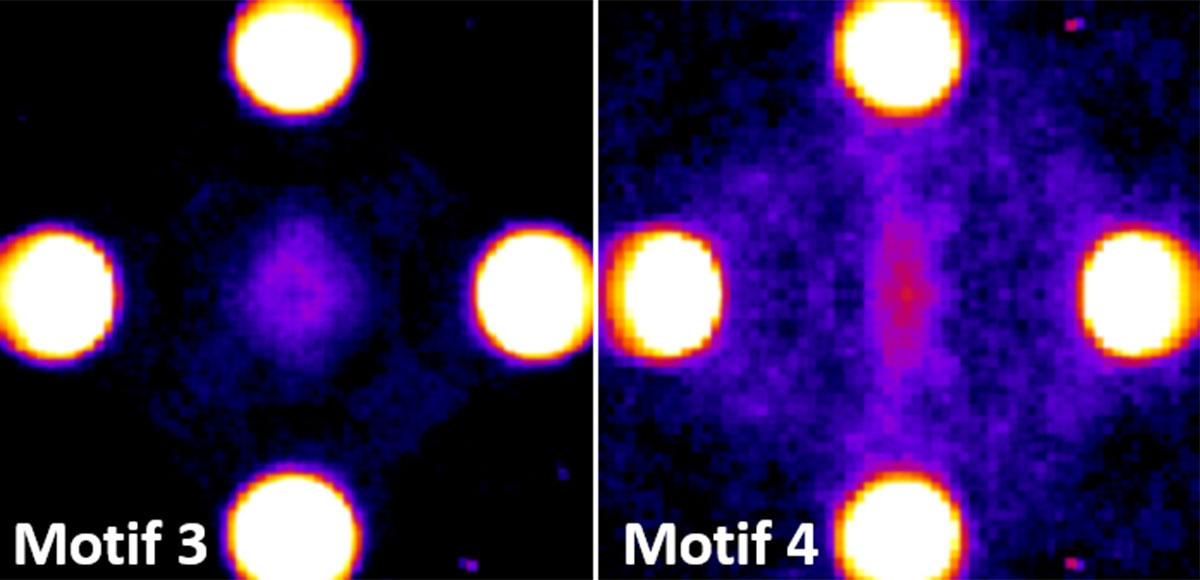

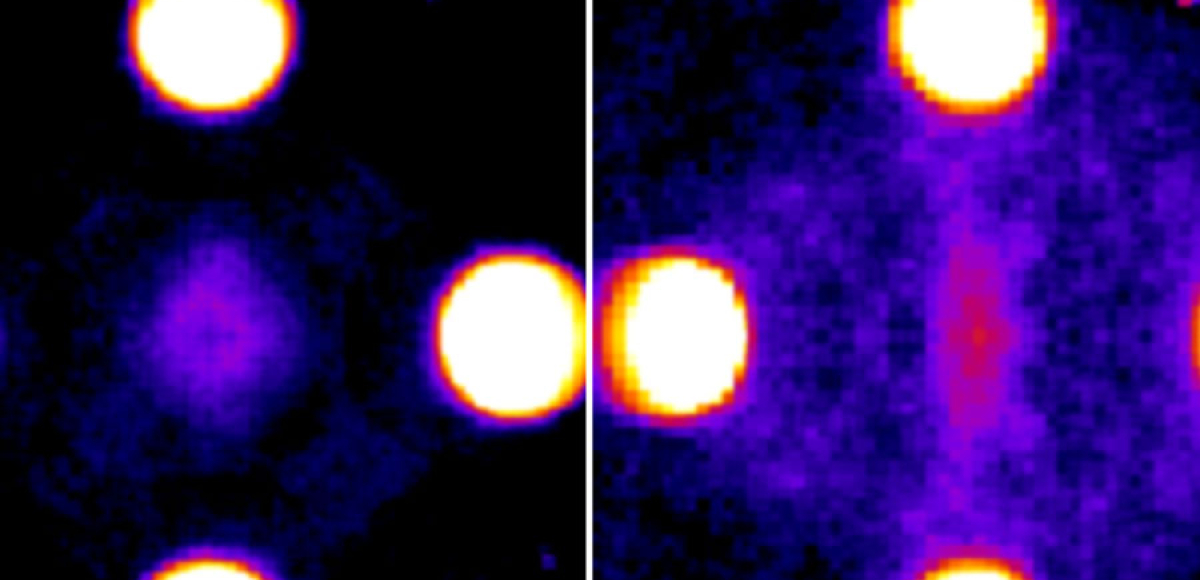

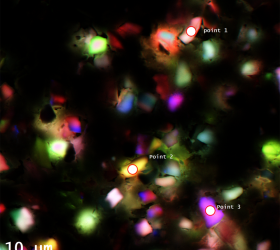

Strain effects in SrHfO3 films grown by hybrid molecular beam epitaxy

ACS Applied Electronic Materials

2025

NEWS

August 04, 2025

October 29, 2024

EVENTS

Feb

10

2026

Webinar

Germany