Advantages:

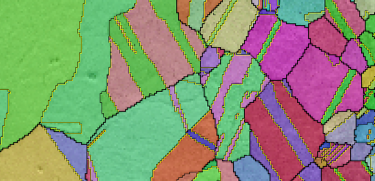

In-situ heating stages allow dynamic microstructural observations and can provide new insights into materials research.

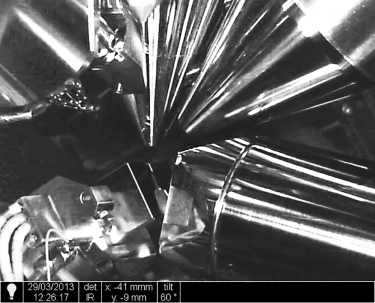

- Modules are specially engineered for the scanning electron microscope (SEM) environment

- Custom designs allow quick fitting and removal from SEM stages so normal SEM use can be resumed quickly

- Designed to be compatible with geometrical requirements of different detectors including electron backscatter diffraction (EBSD) for dynamic observations

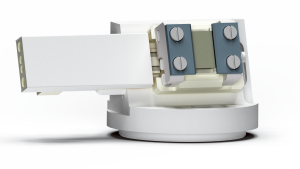

Murano heating stage

- Murano stage available for heating to 950 °C for EBSD applications and secondary electron detector (SED) imaging

- Study real-time crystallization and phase transformations at elevated temperatures up to 950 °C

- Proprietary design enables offline specimen mounting and storage

- Bulk specimen support designed specifically to operate within EBSD/focused ion beam (FIB)/SED geometry constraints

- Water cooling and heat protective shielding ensure maximum protection at elevated temperatures

- Additional bias control to assist with imaging at elevated temperatures

Advanced Materials Research

2014

Model 525

Datasheets

Applications

|

Murano heating stage used in the characterization of advanced high strength steel |

|

|