Getting started with your PIPS II system

- Plug in cables per the installation instructions from the Getting Starting Guide

- If the system has an optical microscope, install it and the PC.

A. Connect the monitor, mouse, and keyboard to the PC. Place the monitor, mouse, and keyboard next to the instrument on the bench. Plug in the power cables for the PC and the monitor.

B. Connect the ethernet cable between the Network connection on the back of the instrument and the Network port on the rear of the PC labeled To ion beam instrument. This is an add-in board. The other network connection can be connected to the internet for remote access.

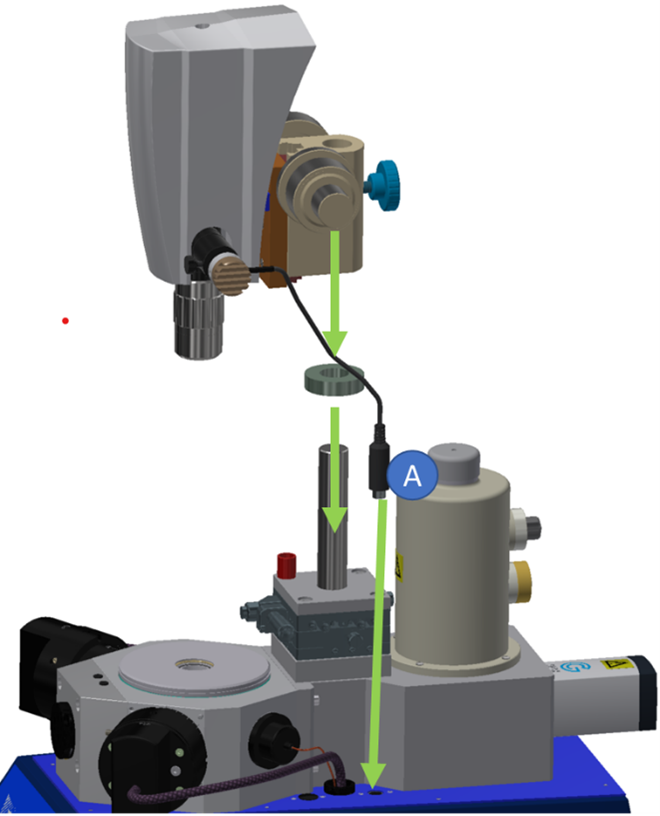

C. Slide the rack and pinion mount onto the post on the top of the instrument.

a. Plug cable A (from the first picture above) into the connector on the top right of the cabinet, as shown.

b. Plug cable B into an available USB port of the imaging PC.

c. Plug cable C into the Camera Trigger port on the back of the instrument.

- Check for a gas-line leak.

- Turn on the power switch directly above the power cable.

- Purge the argon gas line.

- Disconnect the argon hose from the back of the tool.

- Set the flow rate to 172 kPa (25 psi).

- Open the flow valve and let the argon run through the hose for a minute.

- With the argon still flowing, reconnect the hose to the back of the tool.

- Confirm the guns are ready.

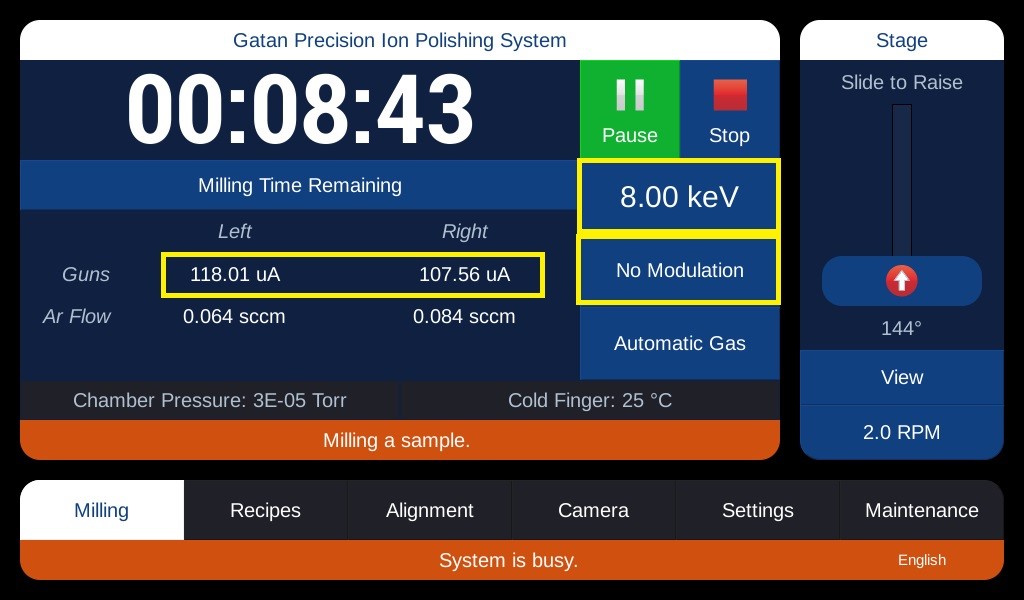

- Start milling at 8 kV and no modulation.

- Confirm both guns have an accelerating current above 20 µA.

- Stop milling.

- Purge the guns overnight.

- Disconnect the cold cathode gauge cable.

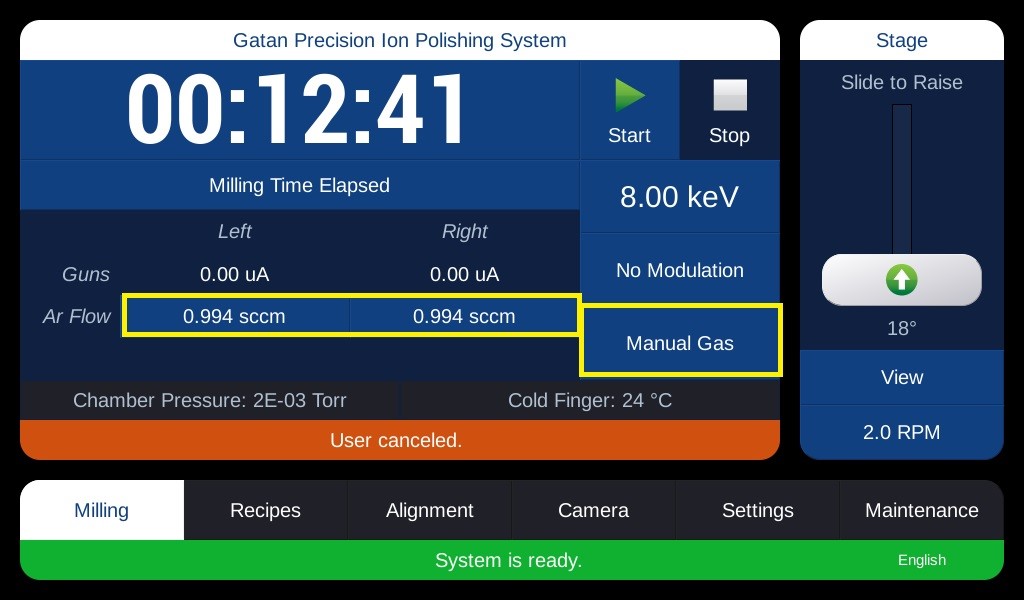

- Set the gas flow to Manual.

- Set both guns to 1 sccm, flow rates may vary significantly, and that is normal.

- Leave to purge overnight.

- Zero the mass flow controllers.

- Connect cold cathode gauge cable.

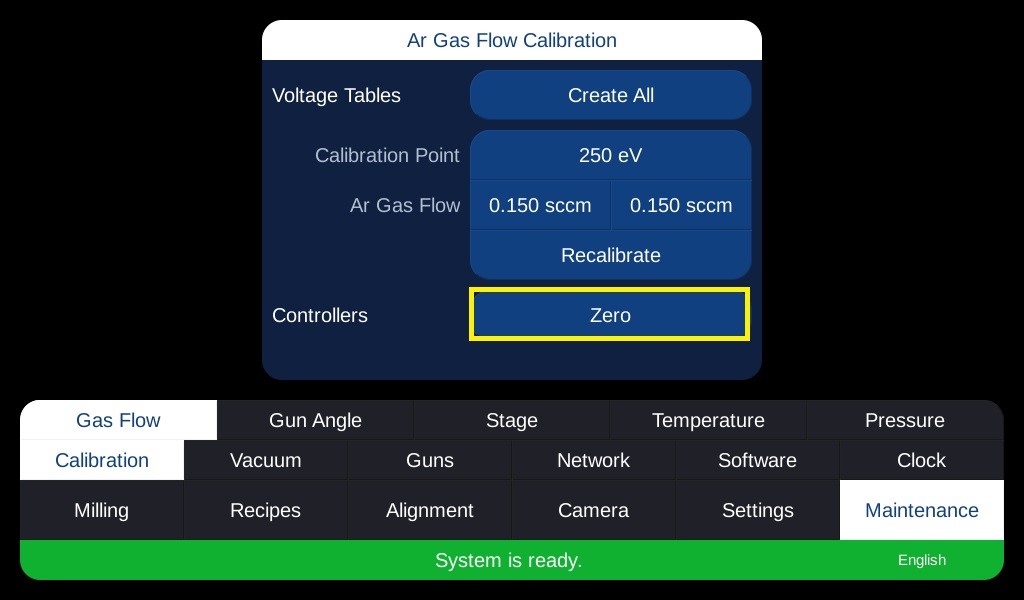

- Set the gas flow to Automatic (see picture above).

- Push Zero (Maintenance / Calibration / Gas Flow).

- Align the guns.

- Watch and follow the instructions from the video below.

- Mount a sample in the clamp type Duopost®.

- Center the interest area of the sample to the axis of rotation.

- Watch and follow the instructions from the video below.

- Video is for FIB lamella but works on any sample type.

- Select milling parameters and start milling.

- Typically, start at 4 – 5 keV, then lower energy to 2 – 2.5 keV before or just after perforation.

- Clean up at 1 keV or lower.

- Gun angles are usually 4 – 6º for the top gun and 3 – 5º for the bottom gun (sample dimpled from top).

- Typically use dual beam modulation with Duopost.

- The rotation speed is usually 3 rpm.

- Most samples benefit from milling cold (with liquid nitrogen) if available.

All parameters are sample-dependent; the suggestion above is only a starting point.